The material used and the technique of custom insole fabrication make all the difference between an insole that works and one that doesn’t. Podiapro makes insoles primarily using the French moulding technique seen below. If patients are unable to visit us, we have alternative techniques to make their insoles remotely.

At the core of our technique is the acquisition of a three dimensional footprint. A correctly acquired footprint enables us to make insoles with precise contouring and corrective elements.

At Podiapro, we follow a 3 pronged approach to making insoles – (1) Analysis (2) Moulding (3) Finishing

The patient’s pain or complaint is clinically analyzed. The analysis is done using one or more of the tools given below depending on which center you visit and the practitioner’s choice:

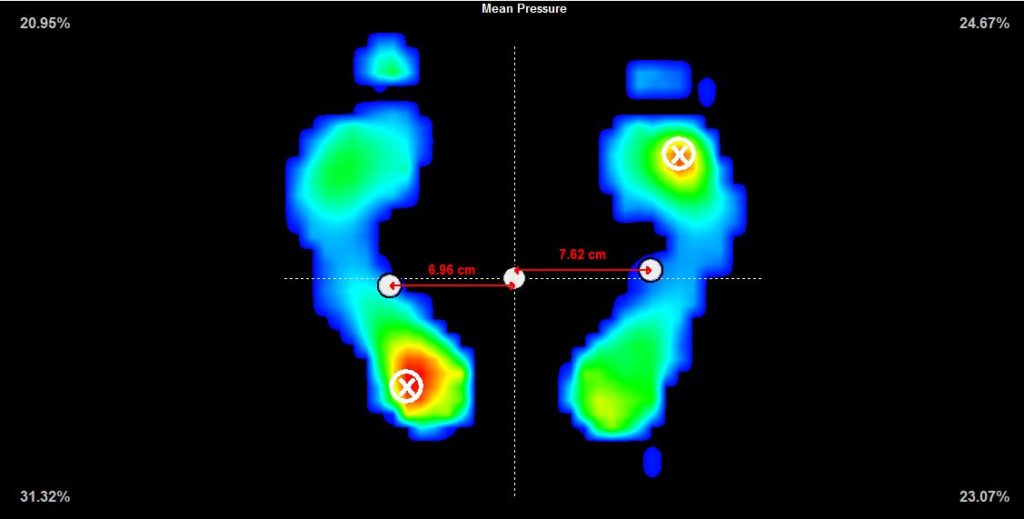

What is popularly called as a foot scan is actually a measurement and analysis of foot weight pressure distribution. Presscam, the advanced pressure plate from Sidas, France, is an outstanding device to measure the weight distribution on your feet in both static (standing) and dynamic (walking) conditions. It shows the high pressure zones, the body’s center of gravity, stability and balance. Made with highly sensitive resistive sensors, the Presscam is excellent to check weight pressure for those suffering from diabetes, corns, calluses so that the high pressure zones can be demarcated to offload.

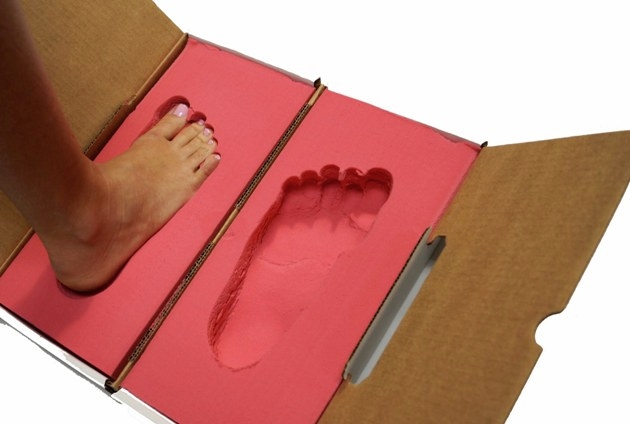

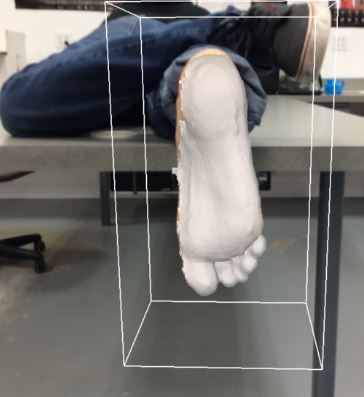

This is the core of our technique – thermo-moulding insoles using a three dimensional foot print which can be acquired by using vacuum-silicon bags, a foam box or a 3D scan of the foot using a 3D scanner. Sometimes the insoles are directly moulded using foam pads and the ‘direct on foot’ technique when the condition of the foot is not grave. The various moulding techniques are briefly described below.

We believe this is the world’s best technique of moulding insoles. A strong footprint is acquired on silicon bags powered by vacuum. This footprint is acquired with the foot being manipulated to rest in the corrected posture.

Since the footprint is formed by the patient standing on the silicon bags in full weight bearing, it is very precise. The cavity thus obtained (negative) is assessed if it successfully puts the patient’s feet in their corrected posture, else the bags are aired and a fresh footprint is taken in less than 2 minutes. Insoles are thermo-moulded inside these negatives, under the patient’s feet, to achieve optimum posture correction.

A foam box is used to take footprints when:

A foot positive is created from the foam box footprint and insoles are moulded on these positives.

Podiapro will soon start making custom insoles and footwear off 3D scans of the feet. These scans make it possible for customers to order insoles and footwear from our master clinic without having to visit us. The footwear made is as precise and accurate as it is when we would make them off vacuum silicon bags.

Stay tuned for more on this.

This is a basic moulding technique where the insoles are moulded directly on the foot while using the foot’s own windlass mechanism to contour the insoles. This works well for cases like over pronation, heel spur, plantar fasciitis. These foam pads are used when insoles are to be made off site as they are lighter to carry.

We also have expertise in making custom insoles off plaster of paris casts of the feet. This is a technique we use with our partner clinics to make insoles for their customers or patients. They send us plaster casts of their patients’ feet and we send them their custom insoles and footwear.

Finishing comprises of working the insole on a grinder to smoothen the edges and flatten the base so it gives stability. Various additional materials may be added as may be required and then the insoles are sanded to fine tune the corrective elements and give it its final touches.

C 1, Gate No. 2, Shreyas Industrial Estate

Off Western Express Highway

Goregaon East

Mumbai, India